Language

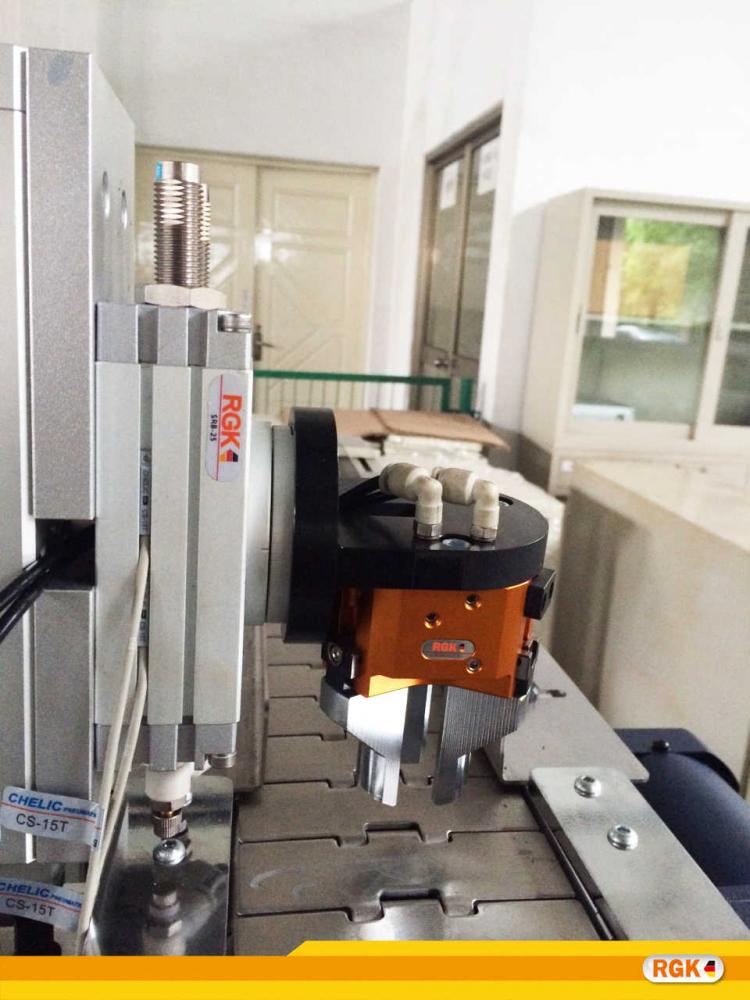

Model:

CMS-30

Intelligent Vacuum Suction Module 30

$51.10

Need Financing?

Finance For As Low As $385/mo.Features

- Space-saving in design

- Specializes in 3C industry for the use of flexible boards or IC boards

- Suitable for any industry

- high and low thickness can reach up to 8mm

- Can be used with a vacuum pump & a vacuum cylinder or with a vacuum generator

- Use and Applications

- IC board Suction

- IC board Convex Suction

- Flexible IC Board Suction

- RAM Suction

- Long IC board Convex Suction

- SMT Suction

- IC Board Suction

- Mobile Surface Suction

Availability:

In stock

SKU

CMS-30

Main Configuration & Parameter

| Size | 40-300 |

| Weight | 0.22~24Kg |

| Gripping Force | 500~34600N |

| Stroke per jaw | 4~30MM |

| Recommended Workpiece Weight | 3.3~170KG |

| How it works | Wedge-hook kinematics |

| Gripper Material | Aluminum alloy |

| Hard Anodized Jaw Material | Steel |

| Drive | Pneumatic filtration of compressed air-dry (10mm) |

| lubricated or non-lubricated pressure medium | Demand for compressed air quality level DINISO8573-1:644 |

| Warranty | 12 months |

| Gripping Force Safety Device | With internal mechanical gripping safety device or mechanical external SDV pressure safety valve |

| Rail | Base jaw heavy load bearing rails, long jaws with minimal shaking. |

| Base Jaw | Jaws connected to work piece. |

| Sensor Systems | Switch reception bracket, switch on the shell can be adjusted |

| Material | Anodized high strength aluminum alloy to reduce weight. |

| Large Oval Piston | Can have greater structural Strength |

| Wedge Hook principle | High power transmission center jaws |

Frequently Asked Questions

Q1: How to measure the data of claw repetition precision 0.01?

A1: This data is the average of one million tests.

Q2: The service life of the gripper and the tolerance of the slide rail?

A2: There is no standard data value and it will vary depending on the environment and mode of use.

Q3: Why is there no standard Finger at the front end of the gripper body?

A3: All fingers are custom made and must be customized according to the customer's function.

Q4: How many points can the gripper be equipped with at most?

A4: 4 sensing points, including 2 reed switches and 2 advanced switches.

Q5: Can the gripper be moved alone?

A5: No, RGN/RZN series grippers are all in the same motion.

Q6: What is the maximum temperature that the gripper can withstand?

A6: 70-80 degrees, high temperature mainly affects the damage of the O-ring in the body.

Q7: Is there any restriction on the length of the Finger of the gripper?

A7: Yes, each model has a limited length. If the limit is exceeded, the wear degree of the gripper slider will be different and the slider will not run normally.

Q8: Does the gripper need maintenance?

A8: Yes, and for a certain maintenance time, but if the use of the environment has dust, iron and aluminum chips, oil pollution... It is recommended to do simple cleaning at high frequency (such as cleaning the slider with an air gun).

More Information

| Model | CMS-30 |

|---|

Reviews

Write Your Own Review